Roll forming machine manufacturer Shenzhen Superda Machine Co., Ltd (https://www.superdamc.com) professional electrical cabinet box roll forming machine, cable tray, floor deck, rack shelf, czu channel profies metal forming machine.

Wednesday, August 21, 2019

Steel house villa

Light steel villas, also known as light steel structure houses, are mainly made of hot-galvanized steel strips that have been cold-rolled by cold-rolled steel.

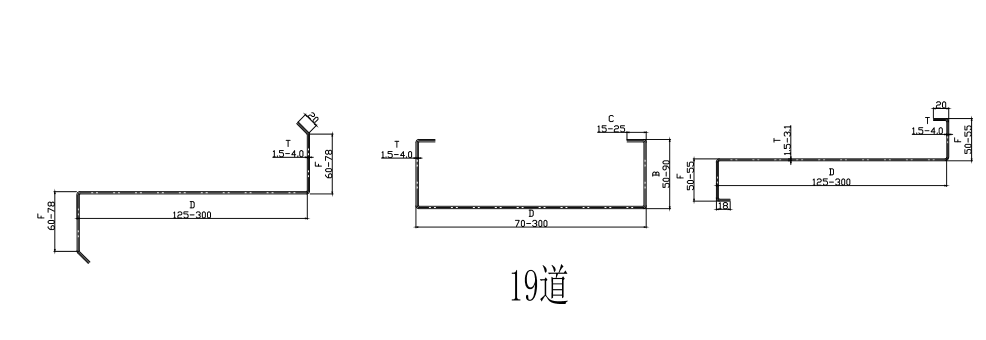

Ⅰ,Customized drywall frame z channel steel keel

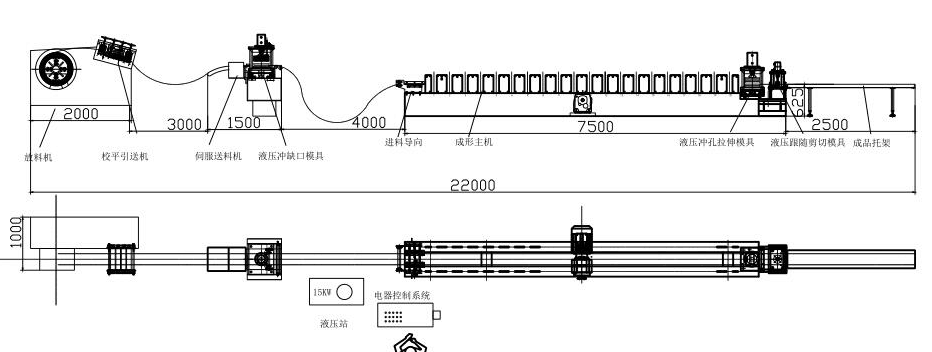

Ⅱ, Drywall frame production line processUncoiler straightener 2 in 1 → Guide device → roll forming machine →shear device (including knife)→ finished product rack

Sunday, August 11, 2019

Bed profile upright beam purlin production equipment

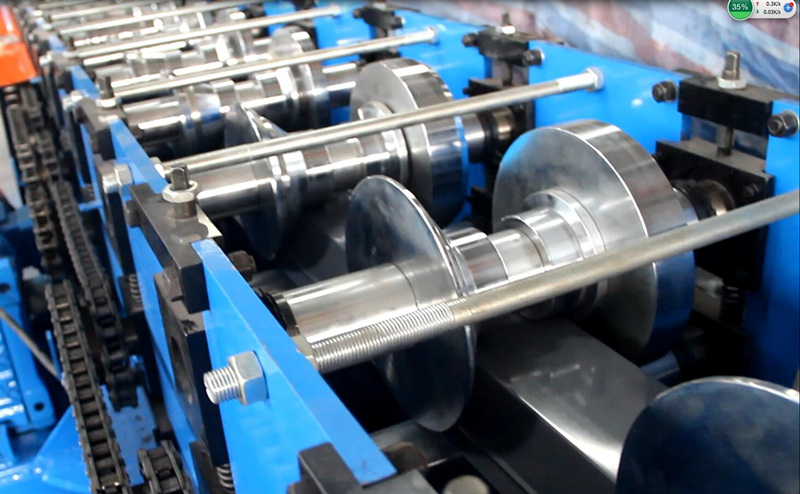

Steel beds are generally divided into single-layer iron beds, double-layer steel beds and three-layer metal beds. Basically, it is made of ordinary iron pipe or angle steel. The iron bed production process is generally metal forming machine-cutting-drilling-welding-sanding-acid washing phosphating-spraying. The places of use are mostly student residences, staff quarters, construction site, apartment, etc.

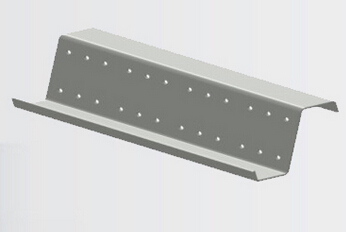

The "steel bed" is also called the iron frame bed. The materials used are divided into three categories, bed upright beam, steel panel, and ordinary angle metal.

The size of the iron bed is generally: 200 length * 100 width * 170 height CM

The lower layer of the iron bed is separated from the ground 35CM, the upper layer is 140CM away from the ground.

The fashion steel bed is used frame bed, the production and processing is very easy, the screw hole made by punch before roller system, metal upright beam with stud and track instead of welding process.

The circular steel bed can make an aesthetic appearance and the processing cost is the highest. Good security. The steel uprigth beam stud and track can be used to make the most solid iron bed, and the processing cost is high, and the appearance is second.

There are about 50 million double-layer iron beds in China used in schools, enterprises, construction sites and other places.

The formed steel purlin bed saves space, is green, and has low cost.

The "steel bed" is also called the iron frame bed. The materials used are divided into three categories, bed upright beam, steel panel, and ordinary angle metal.

The size of the iron bed is generally: 200 length * 100 width * 170 height CM

The lower layer of the iron bed is separated from the ground 35CM, the upper layer is 140CM away from the ground.

The fashion steel bed is used frame bed, the production and processing is very easy, the screw hole made by punch before roller system, metal upright beam with stud and track instead of welding process.

The circular steel bed can make an aesthetic appearance and the processing cost is the highest. Good security. The steel uprigth beam stud and track can be used to make the most solid iron bed, and the processing cost is high, and the appearance is second.

There are about 50 million double-layer iron beds in China used in schools, enterprises, construction sites and other places.

The formed steel purlin bed saves space, is green, and has low cost.

Subscribe to:

Posts (Atom)